Braking

Offbeat with a standard thought process, Braking attempts to make a system stop as fast as possible. From drawing to real-life assembly, our system considers aerodynamics, material mechanics, and thermal expansion to create a design that is reliable and keeps our fellow riders safe.

What does Braking do?

The Braking subteam is responsible for creating a unique, fully functional braking system for our toboggan each year. This system plays a critical role in ensuring the safety of our riders inside the toboggan, and is a critical demonstration of our team's mechanical knowledge. Additionally, braking system performance is one of the key evaluation criteria for scoring during the annual Great Northern Concrete Toboggan Race (GNCTR).

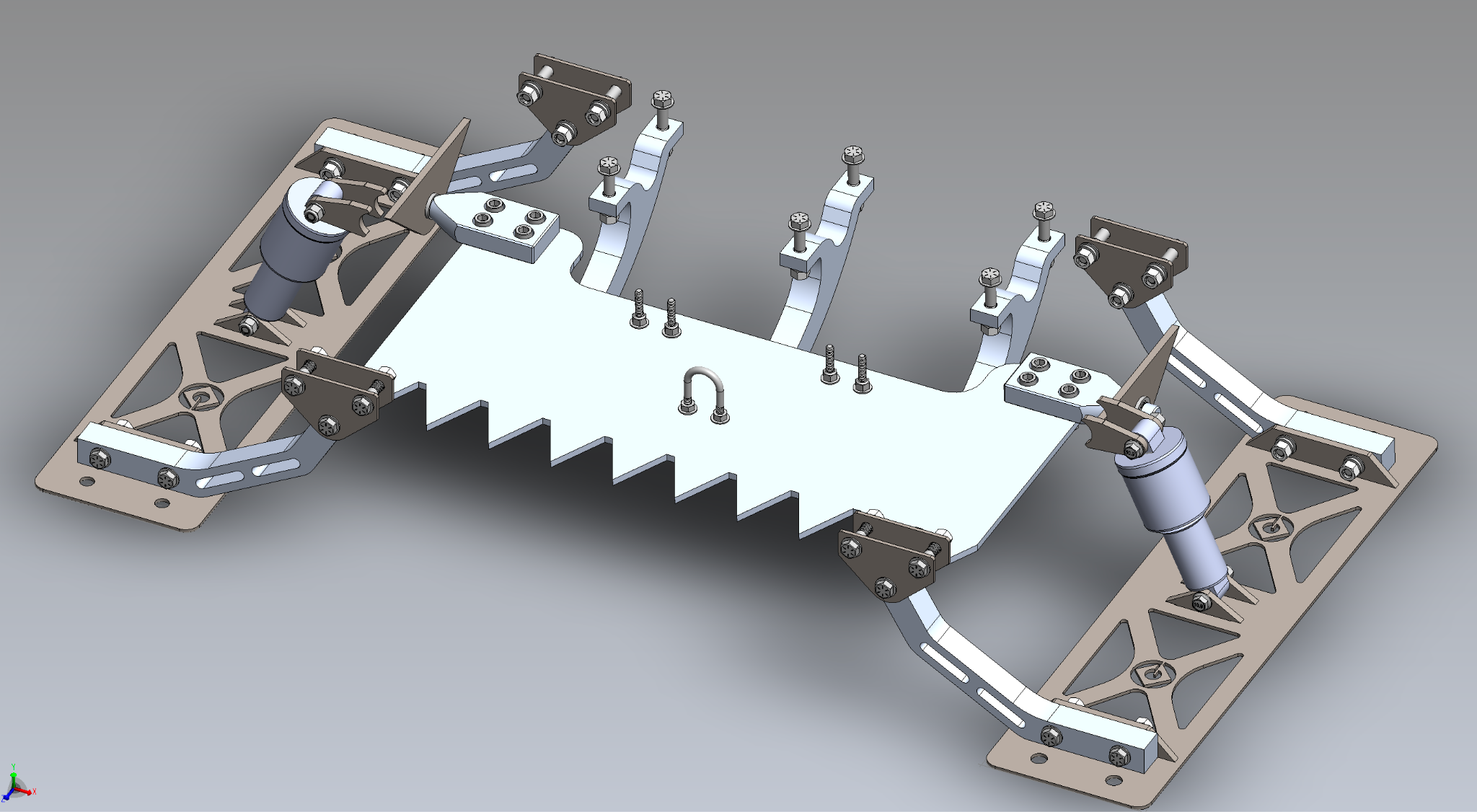

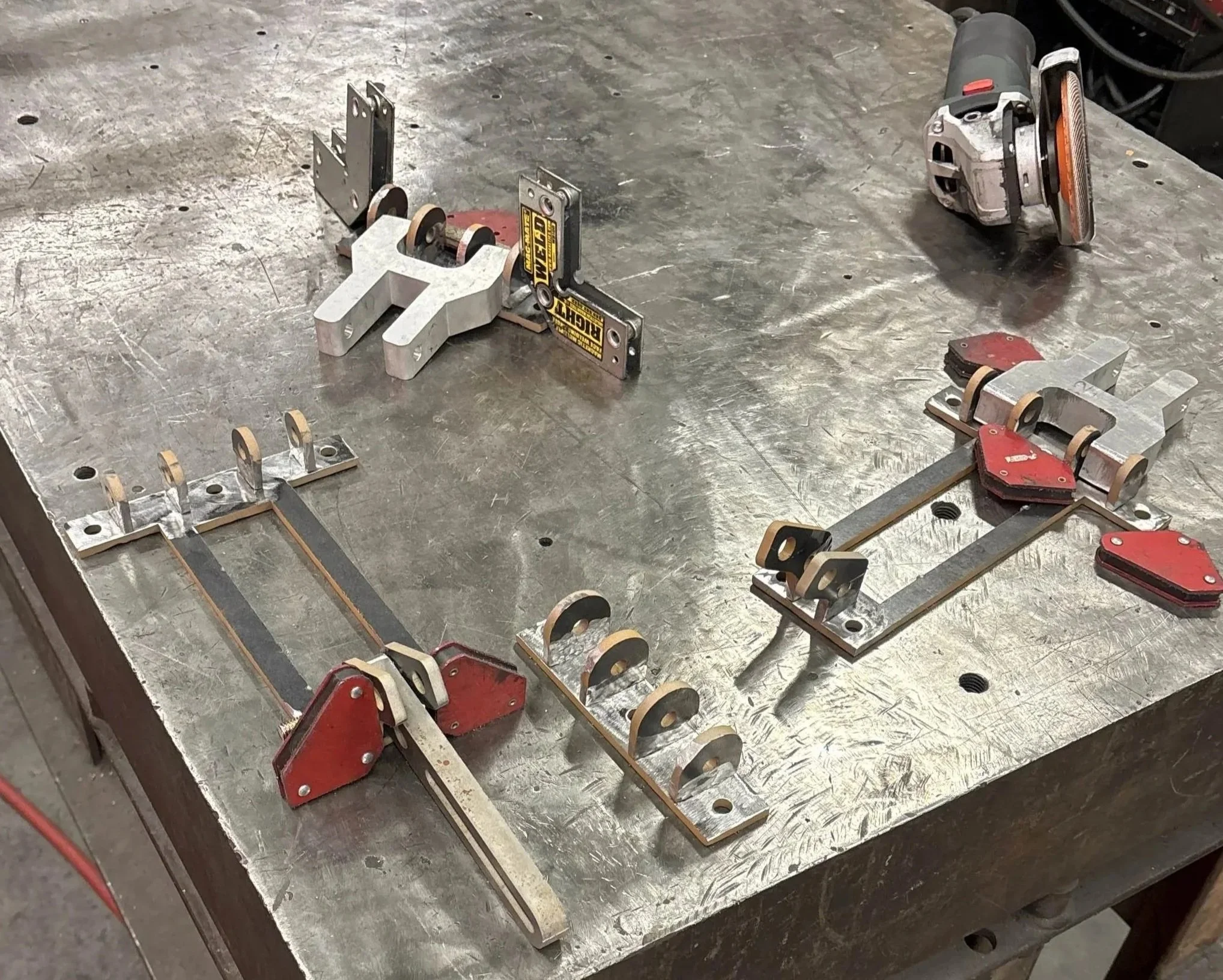

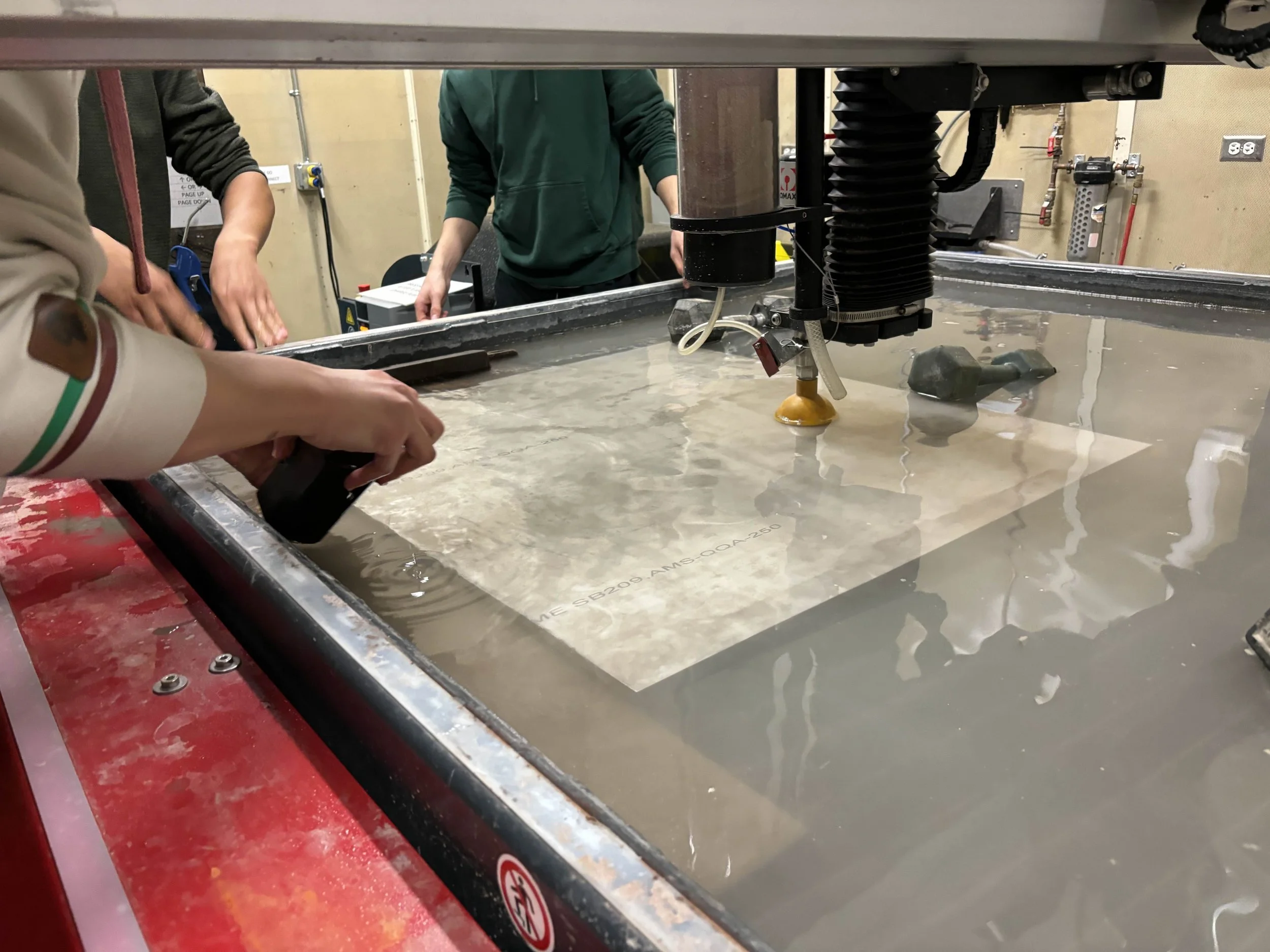

Using engineering design processes, the Braking subteam conceptualizes and then models the braking system using the virtual design software SolidWorks. The brakes are then manufactured using a variety of methods, including waterjet cutting and machining in UBC's Mechanical Engineering shops. Subteam members gain design and manufacturing experience which aids in the development of their professional careers, in addition to soft skills gained by working within a driven, yet supportive team environment.

Depending on the years design, Braking can also be responsible for rear suspension.

Project 1: Electrical Release System

In partnership with the Electrical Sub-Team, The goal is to create electrical and manual release systems for the braking mechanism along with an electrical signal to notify the driver if the brakes were released.